Uncle SEM was equipped with two different specimen holders when he joined the crew: one could only hold one 10 mm specimen stub and the other one was designed to hold bigger samples inside a 26mm wide plate. Unfortunatly, the bigger holder is centered under the objective aperture, so that it was impossible to just put 4 or 5 stubs on its edges and have a complete view of them, since the X and Y movements are limited repectively to 10mm and 20mm.

For these reasons, I decided to build a new rotating stage, so I could fit 6 stubs, so that one of them is always centered under the beam, allowing the observation of the whole sample.

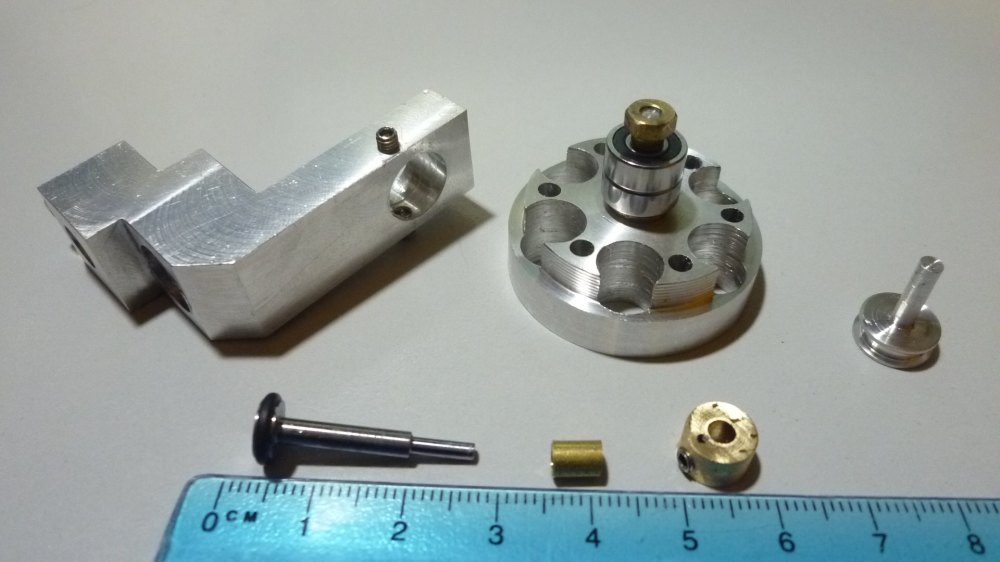

It was a work of both lathe and milling machine. All parts are newly done in aluminium anticorodal alloy and inox steel for shafts. Bearings are used to smooth the rotation of the stage.

Pictures are better than a thousand words:

This was the old specimen holder. The inner plate was machined in order to fit 5 stubs, but it didn’t allow to see the whole surface of them due to limitations in X and Y movements.

Newly machined parts.

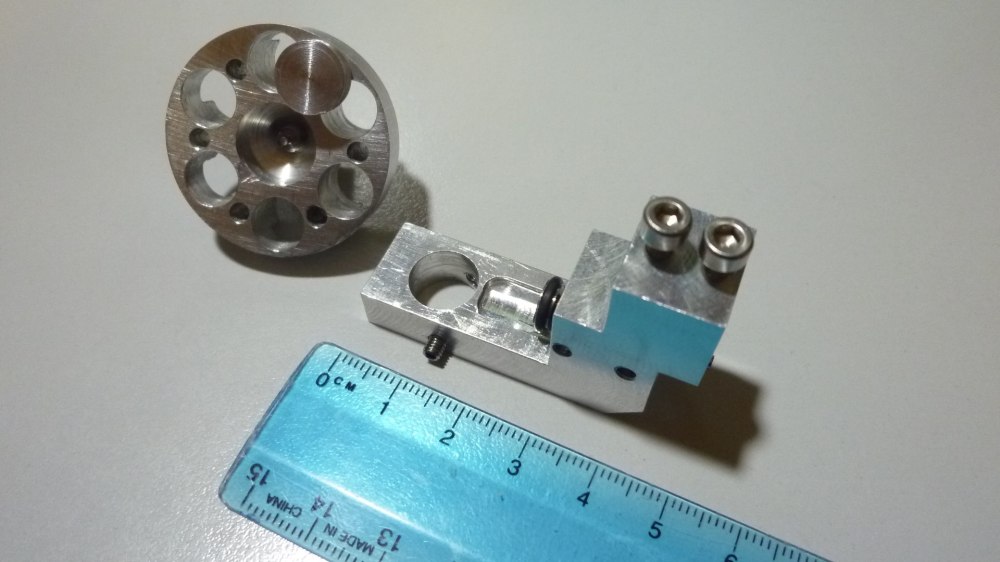

The new holder assembled.

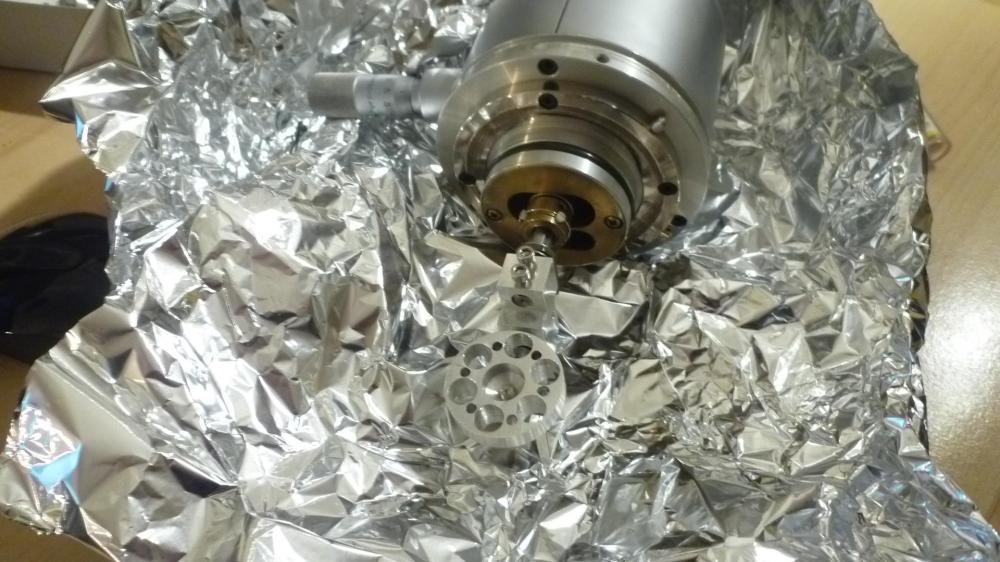

New stage mounted on holder assembly.

A view of the new holder from the chamber-scope.